We utilize the latest technology in GPS for layout and machine control.

Topcon is the first global service provider for true Global Navigation Satellite System (GNSS) receivers.

OUR TECHNOLOGY

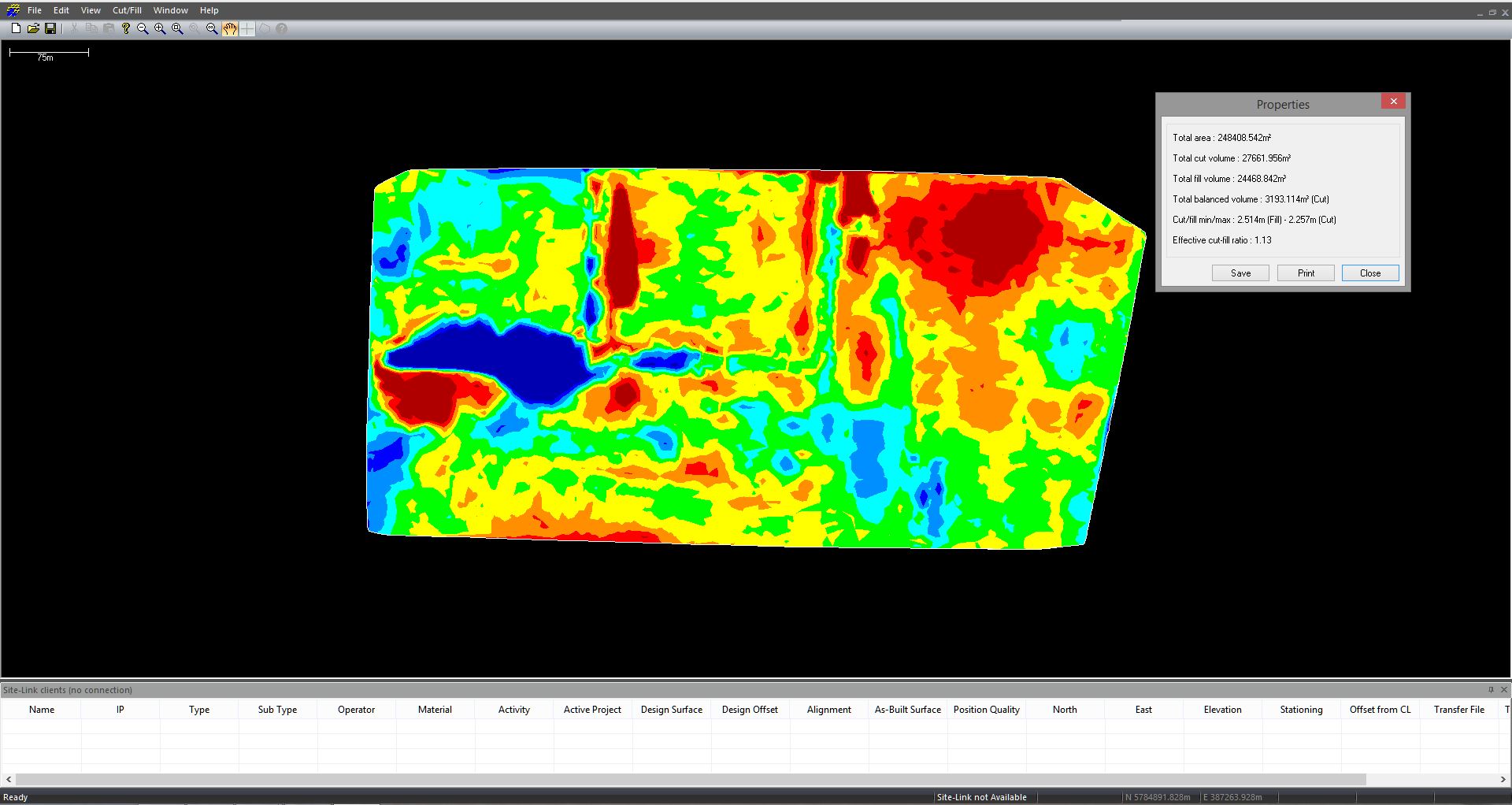

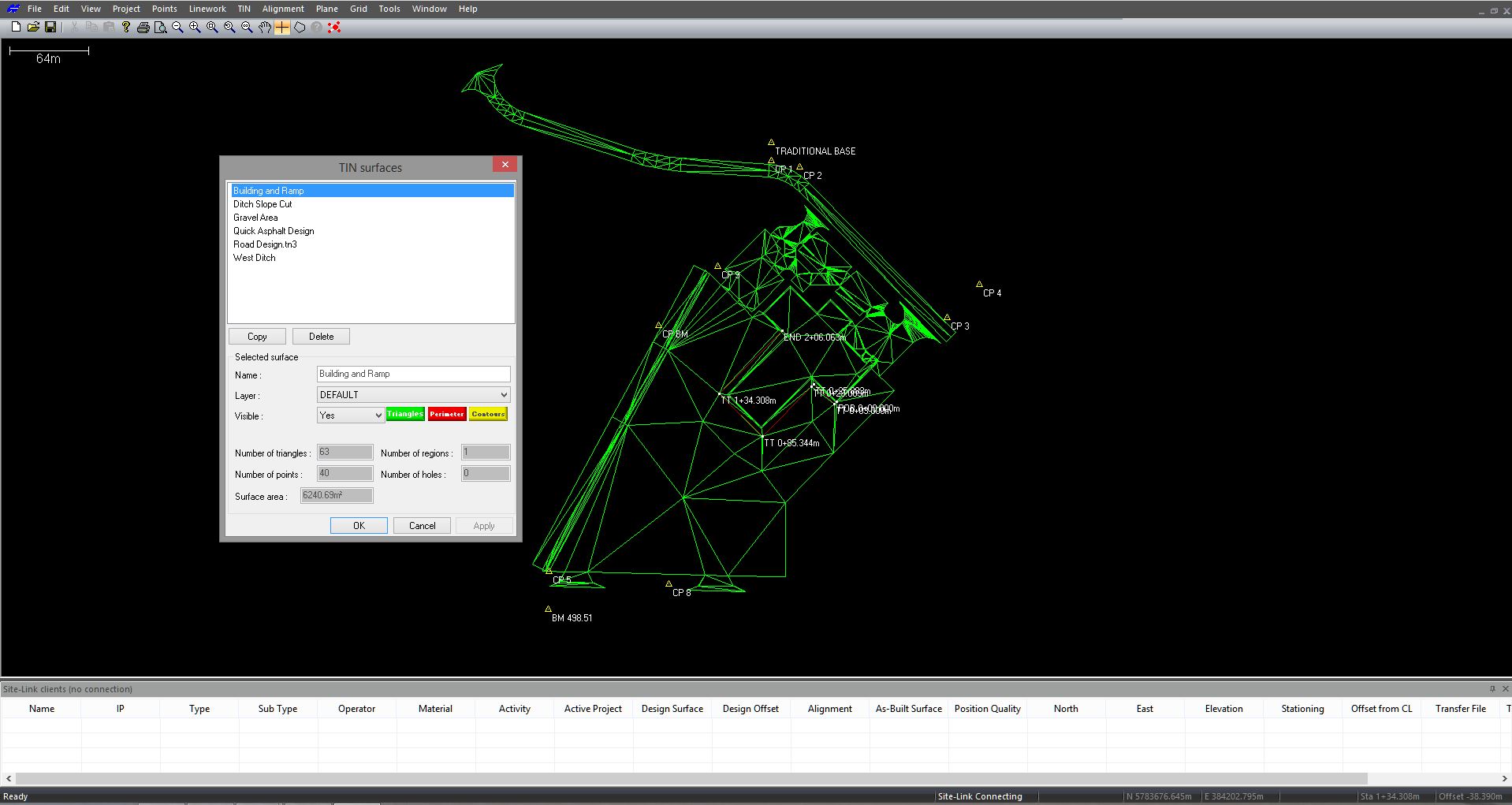

Traditional Contracting Inc. carefully evaluates every aspect and design detail to help identify opportunities to add value and cost savings to every project.

Our highly experienced staff has implemented the most up to date computer software and technologies to ensure that our customers are provided an accurate estimation of their projects.

GPS BASICS

We utilize the latest technology in GPS for layout and machine control. This precision technology is enabled by satellites that send constant radio signals down to site-specific base station antennas and dual receiver machine antennas which triangulate the radio signals to determine the machines exact position on the earth.

This advanced technology not only ensures an accurate finished product with tolerances ranging from 15mm-25mm on average, it also accelerates production levels that translate to an overall cost savings for our clients.

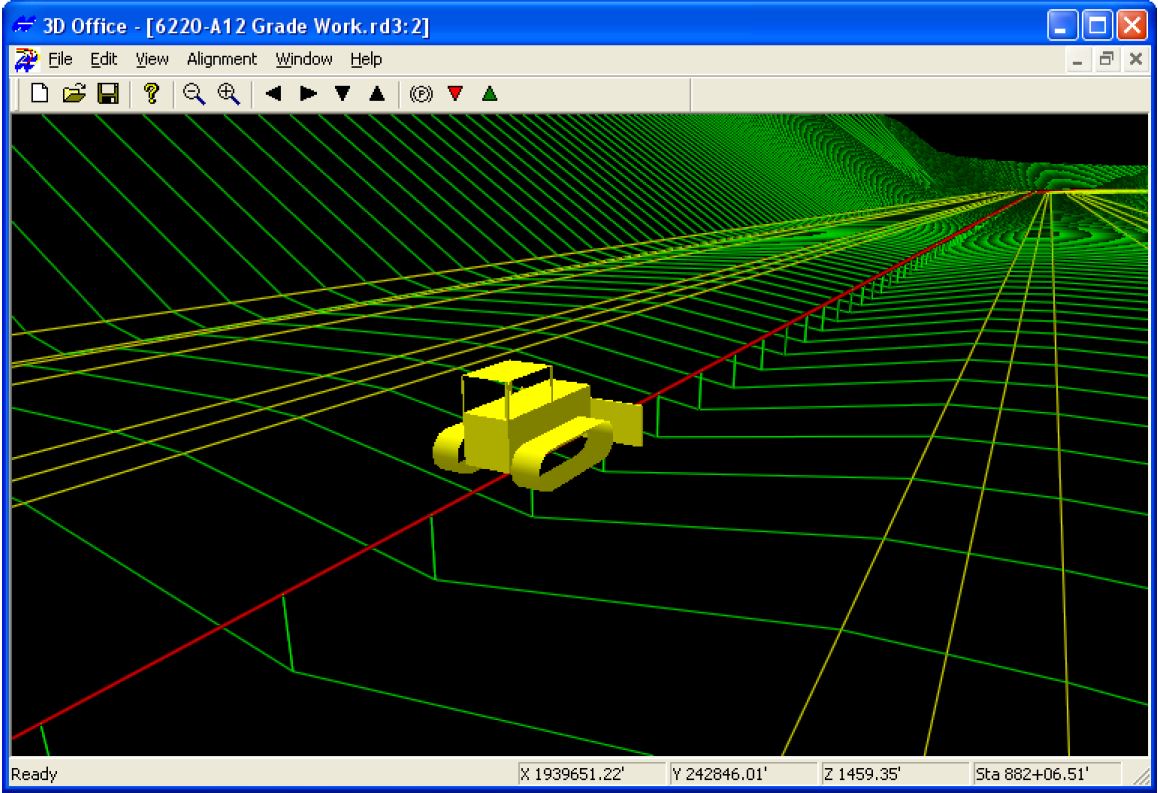

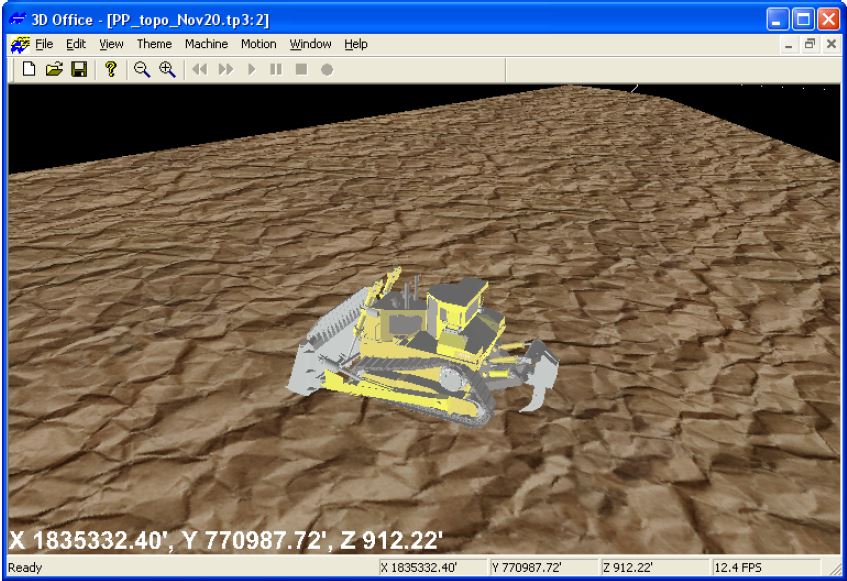

GPS LAYOUT WITH 3D-MC2 FULL MACHINE CONTROL (Dozer)

Outdated finish grading with a dozer took multiple passes at slower speeds. Existing 3D-GPS machine control allowed operators to double their production. 3D-MC2 uses revolutionary technology to reach an unbelievable new level of performance: four times faster than a standard dozer, and two times faster than any standard GPS controlled 3D dozer.

3D-MC2 drastically changes the role a dozer plays on a typical job site, in some cases it may even replace the need for a motor grader. Not only does speed increase, but fewer passes are needed, so more work can be done in less time. We only need to move material once!

3D-MC2 utilizes Topcon's GX-60 control box, GPS+ antenna, MC-R3 receiver and MC2 sensor and pairs them with advanced controlling software to provide position updates up to 100 times per second. The MC2 sensor combines a gyro, compass and inertial sensor to measure the X, Y and Z position as well as the roll, pitch, yaw and acceleration of the dozer. 3D-MC2 provides the most stable and responsive control system possible.

GPS LAYOUT WITH X63 INDICATE MACHINE CONTROL (Excavator)

Topcon's X63 excavator GPS system provides our operators with all the information needed to expedite excavation tasks. Unlike laser excavator systems, X63 enables us to "see" his machine's exact position in relation to the site, enabling precise positioning over utility centerlines. In real time the operator can also see the position of the teeth of the bucket compared to the finish design which is very helpful in deep cuts, blind excavations or when working around structures.

Excavating has never been easier or faster. The X63 uses 360° tilt sensors to track the position of the bucket, and our state of the art GPS+ technology to provide precise position information. Our bright, color touch-screen control box displays bucket position in real time, providing the operator complete control. As well the X63 system eliminates the need for a grade checker to constantly monitor cuts, increasing both safety and productivity. Complex designs can also be manually entered directly in the control box to allow complete flexibility in the field.

|

|

|

|